Making Maize Silage the Easy Way

Farmers and contractors looking to make high quality maize with no fuss can find it in MaizeKing, a locally made maize silage preservative by New Zealand biological solutions company, BioStart.

MaizeKing users enjoy the fact that they can apply the product direct from the drum without dilution and is stable at room temperature. It can also be transported easily and once the drum has been opened, it can be used between jobs and over multiple days, without any wastage of part drums.

In addition, BioStart has developed an applicator with Ascot Pumps that allows MaizeKing application to be easily controlled from within the cab.

“Ease of use, while important for minimising workload, does not come at the expense of creating a reliable preservative. MaizeKing has been developed and extensively tested to ensure it makes a high-quality maize silage that stores well,” says BioStart CEO, Jerome Demmer.

In a response to requests from farmers and contractors, Biostart has now also developed a high-volume form of MaizeKing and SilageKing that can be used in the built-in silage applicator systems in forage harvesters.

Both products can also be used in the forage harverter’s internal tank set up.

MaizeKing and the new MaizeKingHV are both designed to preserve a premium maize silage with minimum fuss, just at different application rates.

MaizeKingHV is available in 1000 L totes and has an application rate of 300 ml /wet tonne (treating 3,330 wet tonne), while their traditional low volume MaizeKing, which matches with the Ascot Pumps is still available in 20 L drums and 1000 L totes and treats 115 mL/wet tonne of forage.

MaizeKing is a mixture of fermentation extracts, nutrients and microbial stimulants and works in two ways.

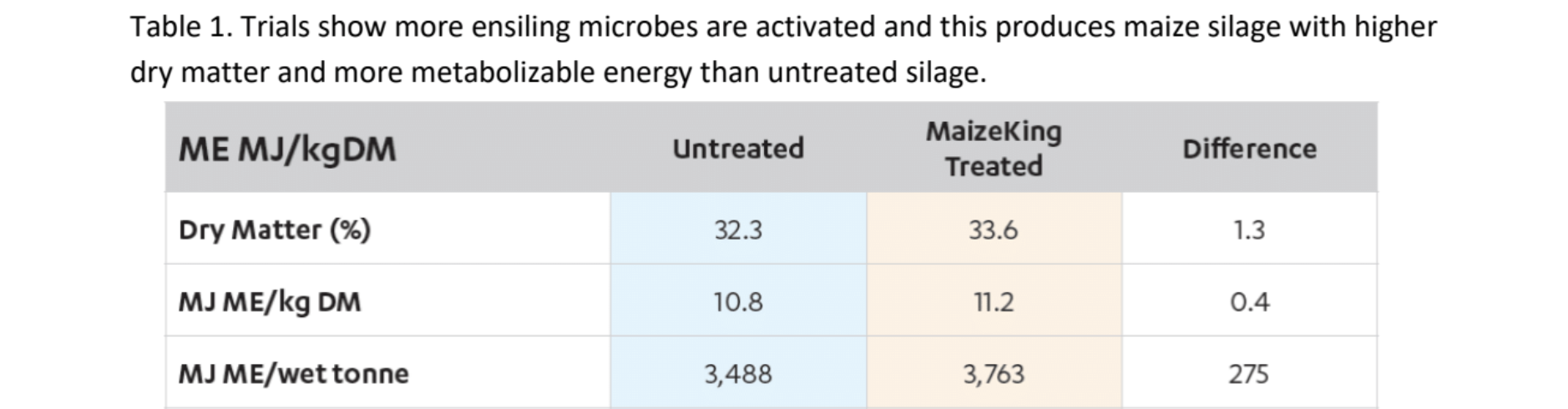

Jerome explains, ‘Firstly, it stimulates the ensiling bacteria that naturally live on the maize forage in the paddock and secondly it suppresses the spoilage microbes that can otherwise ruin the silage.

This dual action benefits the maize feed quality by activating and increasing the number of beneficial ensiling bacteria that naturally occur on forage to produce more of the lactic and acetic acids required to properly ensile maize, while also inhibiting the growth of the yeasts and fungi that use up feed energy, heat bales and produce mycotoxins that affect animal health.’

‘Good silage making practices should also be followed, including harvesting at the optimum moisture level, using the appropriate chop length and excluding as much oxygen as possible in the stack with tight compaction and sealing properly,’ adds Jerome.

For more information contact BioStart on 0800 274 524.